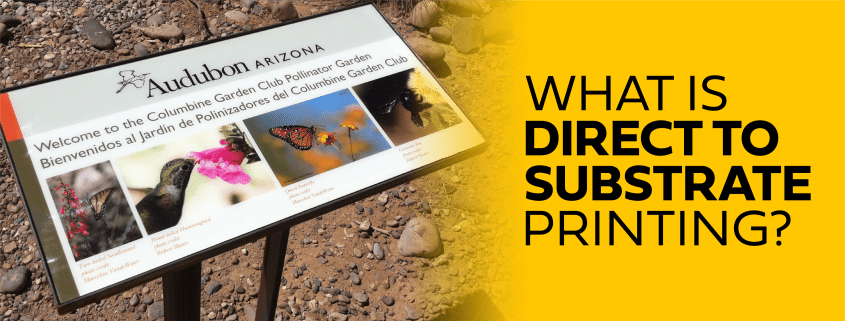

What is Direct to Substrate Printing?

Read time: 4 minutes | Author: PRI Graphics | Posted: March 2nd, 2022

Direct to substrate printing represents a transformative advancement in the printing industry, where it eliminates intermediary steps by applying images straight onto the substrate’s surface. A substrate refers to the base material, such as plastic film, glass, paper, or other textile products such as canvas, onto which the image is printed. The historical approach entailed printing labels or vinyl decals separately before transferring them onto the substrate.

PRI Graphics & Signs, in Phoenix, offers premium, large format flatbed printing services. This article delves into the recent evolution and improvements in direct to substrate printing technology and equipment, which have enhanced affordability and practicality.

Call us today at 602-393-3131 or Toll-Free at 1-877-409-8889 or send us an email.

“I needed a board printed for the base of a physical model we were building for one of our projects

and PRI helped with the print settings and the medium it was printed on.

They did test samples for us quickly so we could decide on a final print.

Once we did, they expedited the board and got it to us the same day.

I always go to PRI for my print needs.

They get it done fast and are always super helpful.” – Abi S.

Understanding the Substrate Printing Process

Substrate printing employs a large flatbed UV substrate printer to apply the ink directly to the substrate. At PRI, we leverage the high-speed Canon 6170 models that boast the ability to print white ink and create a raised texture. The printer applies ink, containing acrylic monomers, onto almost any flat substrate. After application, the substrate undergoes a UV light exposure, leading to the polymerization or bonding of the monomers. This technique results in the formation of the desired image directly onto the substrate.

You can see the speed of this process in action by watching this video.

Diverse Options for Direct to Substrate Printing

The versatility of substrate printing allows for direct application onto various durable and long-lasting surfaces. These include foam core, aluminum/metal, Masonite, MDF, and MDO Plywood, among others. Furthermore, flexible materials such as Flexible PVC, corrugated boxes, Magnetics and Metallics, DiBond/E-Panel/ACM, Styrene, Plexiglass, Ultra Board (in Black or White), and PVC materials can also serve as substrates.

Benefits of Substrate Printing

Direct to substrate printing offers a broad spectrum of options to suit your project or business requirements. Additionally, Be it for indoor promotional displays or vibrant outdoor signage, this printing method ensures weather resistance, durability, flexibility, and reusability.

About PRI Graphics & Signs

PRI Graphicsis a family-owned, Arizona commercial print company. Our in-house professionals include a graphics design teams as well as printing experts who are highly trained direct to substrate printing specialists. We can provide you with professional advice and exceptional printing materials, no matter what the size of your project or budget.

Call our PRI Graphics print professionals today at 602-393-3131 or Toll-Free, at 1-877-409-8889. Or, send us an email if you have any questions about the direct to substrate printing process.

Visit this Millcraft page for more information on Textile Printing Substrates.

Visit this blog post to learn more about the Different Types of Printing that is possible.

About the Author

PRI Graphics – Director, Marketing & Brand Management

PRI Graphics is a marketing and design expert who is passionate about new emerging trends in digital media and business strategy. A member of AMA with a PCM® in marketing management, he continues to strengthen his knowledge and skill sets in the marketing ecosystem. Prior to joining PRI, he pursued a career in filmmaking and carries on the passion for brand development.